Exploring the Applications of 3D Printing

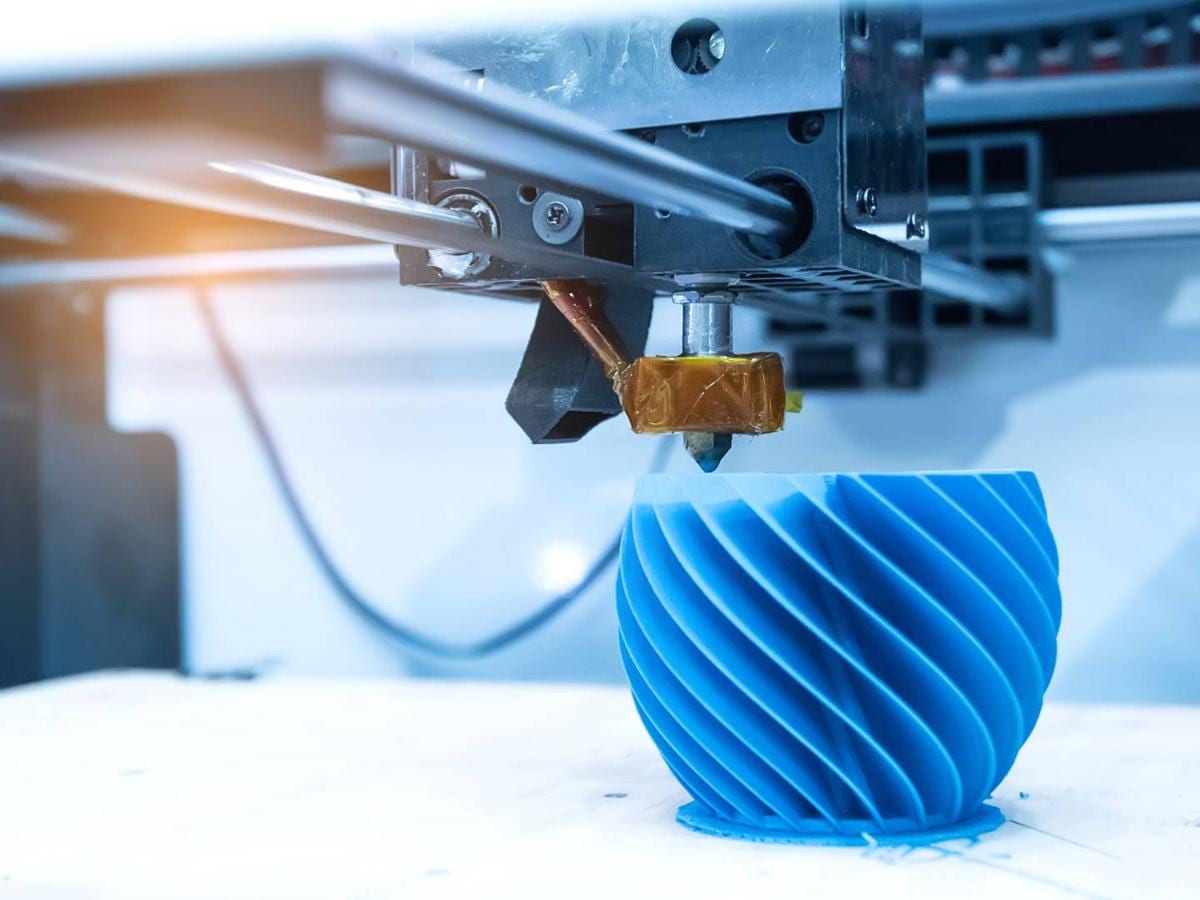

3D printing, also known as additive manufacturing, has emerged as a groundbreaking technology with the potential to revolutionize various industries. In this article, we explore the key features and applications of 3D printing, its impact on manufacturing, healthcare, and design, as well as its future possibilities.

3D printing, also known as additive manufacturing, has emerged as a groundbreaking technology with the potential to revolutionize various industries. In this article, we explore the key features and applications of 3D printing, its impact on manufacturing, healthcare, and design, as well as its future possibilities.

Additive Manufacturing and Design Freedom

One of the most significant advantages of 3D printing is its ability to create complex three-dimensional objects layer by layer, using a range of materials such as plastics, metals, ceramics, and even biological materials. This additive manufacturing process offers unparalleled design freedom, enabling the production of intricate geometries that were previously difficult or impossible to achieve using traditional manufacturing methods. Designers and engineers can optimize product functionality, reduce material waste, and create customizable, personalized solutions tailored to specific needs.

Transforming Manufacturing

3D printing has the potential to disrupt traditional manufacturing processes. It enables on-demand production, eliminating the need for large-scale inventory and reducing supply chain complexities. The technology allows for rapid prototyping, facilitating iterative design improvements and accelerating product development cycles. Small-scale production runs become economically viable, catering to niche markets and customized products. Additionally, 3D printing supports decentralized manufacturing, enabling localized production and reducing transportation costs and carbon emissions. As technology advances and materials continue to expand, 3D printing is poised to play a significant role in the future of manufacturing.

Revolutionizing Healthcare

The healthcare industry has been profoundly impacted by 3D printing. It has enabled the production of patient-specific medical devices, prosthetics, implants, and anatomical models for surgical planning. Surgeons can practice complex procedures on accurate replicas of patient-specific organs, enhancing surgical precision and reducing risks. 3D bioprinting holds the potential to revolutionize tissue and organ transplantation by creating functional living tissues in the laboratory. This technology opens doors to regenerative medicine, providing hope for patients awaiting organ transplants. Additionally, 3D printing has enabled the development of pharmaceuticals with personalized dosages and tailored drug release profiles, improving treatment outcomes and patient adherence.

Advancements in Design and Education

3D printing has transformed the design and education sectors. Architects and designers can create intricate models, allowing clients to visualize concepts and make informed decisions. Educational institutions use 3D printers to enhance learning experiences, enabling students to bring their ideas to life and understand complex concepts through hands-on exploration. The technology promotes creativity, problem-solving skills, and interdisciplinary collaborations.

3D printing has emerged as a game-changing technology with far-reaching implications. Its potential to transform industries such as manufacturing, healthcare, and design is undeniable. As technology continues to evolve and becomes more accessible, it holds the promise of revolutionizing production methods, improving patient care, and fostering innovation across various sectors in the years to come.