How Microchannel Condensers Improve System Efficiency

Microchannel condensers are revolutionizing the HVAC and refrigeration industries, offering significant advantages in terms of efficiency and performance. Their unique design, featuring a smaller and more compact structure compared to traditional condensers, allows for enhanced heat transfer capabilities. By analyzing the mechanics and advantages of microchannel condensers, we can better understand their impact on system efficiency.

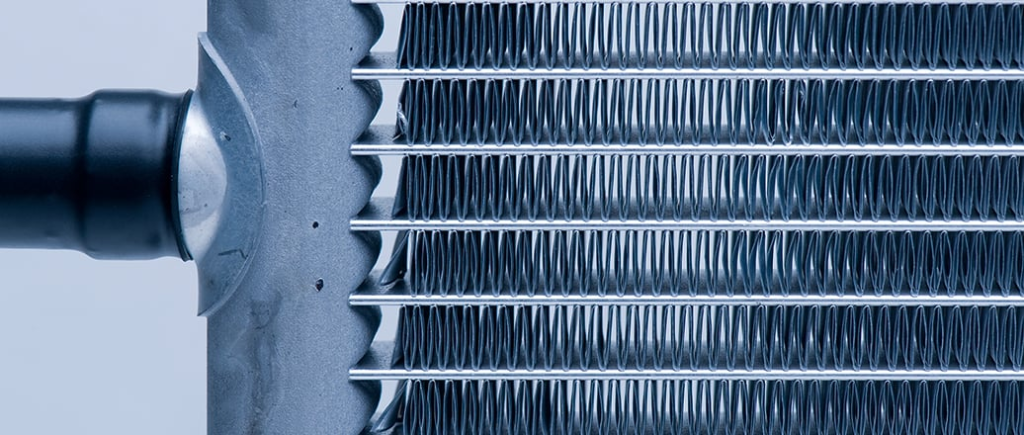

Enhanced Heat Exchange

The primary mechanism behind microchannel condensers is their ability to provide a larger surface area for heat exchange. The arrangement of the channels offers a way to increase the contact between refrigerant and air, thereby improving thermal conductivity. This increased efficiency leads to lower energy consumption across various applications. The unique fin design also contributes to better airflow, enhancing the overall performance of the system.

Compact Design and Weight Reduction

One of the most notable advantages of microchannel condensers is their compact size. These condensers are typically lighter in weight than traditional options. This reduction in size and weight not only facilitates easier installation but also allows for more flexible design configurations within HVAC systems. The smaller footprint means that manufacturers can create more streamlined units without sacrificing performance.

Environmental Impact

Microchannel condensers also align with modern sustainability goals. Due to their increased efficiency, they consume less energy, translating to lower greenhouse gas emissions. Many systems employing microchannel condenser technology utilize refrigerants with a lower global warming potential (GWP), contributing to a more environmentally friendly approach in cooling and heating applications. As regulatory standards become stricter, the adoption of these efficient systems is likely to increase.

Performance in Extreme Conditions

Performance in varying ambient conditions is crucial for HVAC systems. Microchannel condensers excel in high-temperature environments, where traditional condensers may struggle. Their ability to maintain performance under stress is attributed to their design, which minimizes temperature differentials and optimizes refrigerant flow. This ensures that systems operate effectively even in challenging situations, making them a reliable choice for diverse applications.

Cost-Effectiveness

Despite the initial investment in microchannel technology, the long-term savings in energy costs can outweigh the upfront expenses. The efficiency gained translates to reduced operational costs over the lifespan of the equipment. Additionally, the durability of microchannel condensers can lead to lower maintenance costs, making them an economically sound choice for businesses focused on sustainable practices.

Future Trends

As technology advances, the integration of microchannel condensers in new HVAC designs is expected to rise. Innovations such as smart sensors and IoT (Internet of Things) connectivity will enhance the control and efficiency of these systems. Ongoing research into materials and design will continue to push the boundaries of what microchannel technology can achieve, further solidifying its position as a leading choice in the industry.

A Result: The integration of microchannel condensers into HVAC and refrigeration systems represents a significant leap toward improved efficiency and sustainability. As these innovative condensers gain traction, their impact on energy consumption, environmental preservation, and overall system performance cannot be overstated. The shift towards more compact, efficient, and eco-friendly solutions is a crucial step forward for the industry.